How to make envelope glue

A simple and easy homemade envelope kneading recipe. It’s a great alternative to store-bought adhesive when making your own envelopes for your cards. A simple and easy homemade envelope kneading recipe. It’s a great alternative to store-bought adhesive when making your own envelopes for your cards.

If you’re making your own envelopes, you’ll need a special glue recipe. This is how to make envelope glue that will dry on the paper and wait to be activated by water.

Also, the glue needs to be lickable, because of how many people get the envelope wet. This glue is completely edible – every ingredient in it is safe to eat.

When I first started making handmade envelopes, I noticed a problem: I had to glue all my creations together using regular Elmer’s glue. Which, you know, isn’t a problem aesthetically…but as far as utility goes, well, I’m sure the recipients of my letter had to tear their envelopes with all their might to open them. Enter envelope glue … lick-sealed envelope glue, anyway! Made with four ingredients I always have on hand (well, minus the gelatin). Needless to say, my letter writing world was rocked.

Once you’ve made some handmade envelopes using my tutorial, you’ll want to assemble your envelope glue ingredients to make this recipe:

- 3 tbsp white vinegar

- 1 packet gelatin (unflavored)

- 1 teaspoon vanilla extract

- 1 tablespoon of sugar

- Envelope Glue Ingredients

Once you’ve assembled the ingredients to make the envelope glue, pour the vinegar into a container with a lid, like the one I’m using here. The reason you’ll want to do this is because once you’ve made your glue, you’ll need to refrigerate it because it’s a food product that will mold if left out. will go

Hello everyone, how are you? It’s Andrea from Cottage Market and I’m back with you today to make DIY envelope glue and it’s great for stickers too! This is a very simple but very powerful project. If you’re wondering how you make an envelope adhesive … then this post is for you! Many of you love the wonderful world of scrapbooking and this glue will enable you to create stickers… envelopes and more. It’s fast…easy and exactly what you want in this day and age! It also uses very few ingredients, in fact you may already have everything you need in your kitchen right now. Next time we meet, maybe we’ll do a tutorial on making our own stickers and handmade envelopes with some pretty graphic fairy images. Ok let’s get straight to making this glue!

- White distilled vinegar

1 packet of Originate gelatin unflavored

- Measuring cup

- pot

- The bowl

- spoon

- A teapot for boiling water

- Craft supplies

Bowl with Gelatin Step 1: Here’s the easy recipe. First you empty a packet of gelatin into your bowl…

Mixing the Envelope Glue Step Two: Next add 8 ounces of boiling white distilled vinegar to the mixture (make sure you boil it first.

Mixing the sticker glue Step 3: Stir the liquid until it is completely dissolved.

Homemade Sticker Glue in a Jar Step 4: Pour the mixture into a jar that you close tightly and let it cool. (This glue works just fine even though it’s on the thin side.

Adding household glue to the envelope

Then it is ready to use. You can put a thin layer on the flap of a homemade envelope…or the back of some homemade stickers etc! You can use a paint brush to apply it. Once you glue the homemade envelope… let it dry completely and then store it in a plastic container… baggie or other sealed storage. When you’re ready to use, pop it out… lick it off with your tongue, or lightly wet a sponge and stick it on!

DIY envelope glue

Store your glue as you would any other glue, no need to refrigerate it. So fun and easy right? And this mixture will be great to make with kids after it cools down. I am sure they will enjoy some paper creations with this glue.

Vinegar in a container

Microwave the vinegar until warm, about 30-45 seconds. If you’re like my mom and you don’t believe in microwaves, you’re welcome to boil it on the stove. The whole point is to dissolve the gelatin

Add the gelatin to the vinegar and stir to dissolve. Once the gelatin is dissolved, add the sugar and vanilla extract. You should end up with a warm, watery mixture that is exactly the color of honey.

Prepared envelope glue

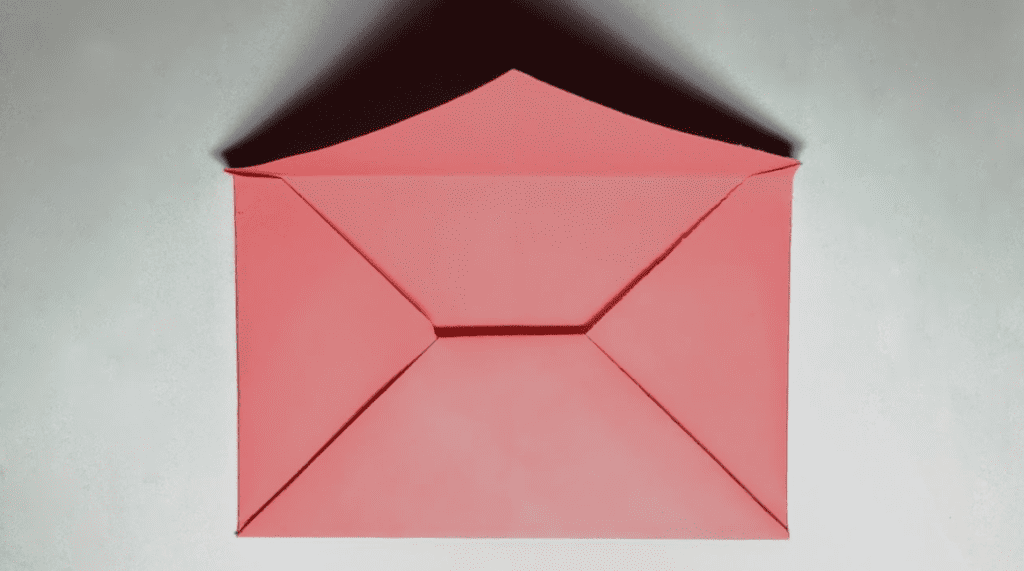

Now you’ve made envelope glue! Next, you’ll place your envelope on a flat surface with the flap facing up and brush your envelope glue onto the edges of the flap, like this:

Gluing

Let the glue dry completely (I give it a few hours), and now you’ve got a lick-seal handmade envelope! As for the leftover glue, cover it and keep it in the fridge. Remember that this will only last for two weeks, so try to make as many envelopes as you can in that time frame to use it up. Any time you want to use it again, you’ll need to restore it to its liquid state in the microwave (otherwise, it just looks like solid jello).

Instructions

Microwave vinegar in a jar of baby food for about 35-45 seconds (depending on the power of your microwave).

- Add the vinegar to a small saucepan and bring to a boil.

- Add in the gelatin.

- Stir to dissolve it completely.

- Add sugar and squeeze and stir some more.

- Use a brush to apply it to homemade envelopes or stamps and let it dry for several hours.

- Store unused glue in the refrigerator to prevent mold.

- Add gelatin, flavoring and sugar.

- Stir to dissolve the gelatin.

- Start by boiling the vinegar in a pan.

- Add the gelatin and stir until it dissolves.

- Add the vanilla extract and stir until well mixed.

- Apply a thin layer to the back of the envelope flap while still hot brushing. Keep it aside and let it dry.

- Wet the envelope for adhesion and press it closed

- Store the unused mixture in an airtight container and to re-apply the glue to the envelopes, heat the mixture in a pan and reapply it to the envelopes while it is hot.

If the gelatin doesn’t dissolve, microwave it again for 10 seconds at a time until the gelatin dissolves and liquefies.

Using a bristle paintbrush about 1/2″ wide, “paint” the glue in a very thin layer onto your envelope flap. When completely dry, dampen as normal and seal the envelope. Close To do this, press the flap closed.

Enough for about 25 quarter-fold envelopes.

This glue is a food product. Store unused glue in the refrigerator for up to 2 weeks. To reuse the glue, reheat in the microwave in 15-second intervals over low heat until re-liquified.

Sealing handmade envelopes

Ever since I posted on making your own envelopes I’ve been getting a lot of inquiries about how to stamp them. Here are some options I like to use.

If I’m delivering a card by hand, I like the recipient to be able to open the envelope without destroying it, so I use a handmade semi-permanent glue dot.

To make these I secure my wax sheets with little glue dots or rhinestones and beads. I applied small dots of Tombow Multi Adhesive to the wax paper, let them dry at least overnight and they were ready to use. They will hold the envelope closed but because the dry adhesive is semi-permanent you can open and re-open your envelope over and over again.

You can also apply Tombo multi-adhesive or double-sided glue pen directly to the envelope and let it dry. It also turns into a temporary adhesive after the glue dries. Just make sure the glue is completely dry before touching anything or you’ll have a permanent bond.

I am looking for a way to put adhesive strips on the tabs of handmade envelopes. I would like the adhesive to stay dry on the envelope and only stick when it is licked/wetted–like on normal envelopes.

This has historically been done with gum arabic, but I have not been able to find a “recipe” for properly mixing gum arabic for this application. Additionally, gum arabic appears to come in different forms (powder, granule, or liquid) so it is unclear how to begin using it as a lickable adhesive. Gum Arabic seems to be used mostly as a paint additive these days.

Does anyone know how to make or buy this type of adhesive and have instructions for its proper use?

I (mostly) followed the instructions kindly provided by @Nothingismagick.

After finding food grade gum arabic and yellow dextrin on Amazon and clove oil at Whole Foods: Ingredients

I followed the instructions in the reply. Everything went well until I tried to dissolve the yellow dextrin. 25 g of dextrin and 50 ml of water produced a mixture that was difficult to dissolve. I got impatient and added too much water to the dextran.

The end result was a solution that was too thin. It simply soaked and stained the paper without creating a lickable layer. I kept the jar uncovered on the radiator for a few days and it halved the volume. The solution thickened — like maple syrup. It works much better, but I think I should reduce it even more. Here is the final result.

I will try again and be more careful/patient when mixing in the yellow dextrin and water!

Highest score (default)

tldr Classic envelope glue is made from gum arabic and yellow dextrin. Both gum arabic and yellow dextrin dissolve in hot water. To prevent decay, refine with copper ions and a drop of clove oil. Put on paper.

- 100 ml of distilled water

- 10 grams of gum Arabic (powder)

- 25 g yellow dextrin (or 20 g tapioca starch + 10 g sugar)

- 1 drop of clove oil

- You can buy gum arabic online or at better art supply stores – take whatever form you can get your hands on. If it is in crystalline form (the size of semi-irregular rock salt) crush it with a mortar and pestle.) Use only distilled water. A copper pot is not absolutely necessary, but copper ions are antimicrobial and antibiotic. The clove oil can be replaced with peppermint oil or left out if you don’t plan to store it.

Crush the gum Arabic with a mortar and pestle and then soak overnight in a copper vessel with 50 ml of water. In a glass bowl, sift the dextrin (or starch and sugar) into the remaining 50ml of water and mix until the water is cloudy and no lumps remain. Heat the water and gum arabic mixture, but do not bring to a boil! Add a drop of oil and gently stir in the dextrin with a stainless steel hand. Continue stirring until the solution gels. Remove from heat and pour into clean and dry mason jars.

When cool, lightly brush over your paper envelope and let dry (or use a blow dryer to speed drying). If it becomes too thick, dilute with distilled water. Store in a cool and dark place. Do not freeze, use within 6 months.

Bonus: To make the yellow dextrin, spread 500g of tapioca starch on a dry, ungreased cookie sheet and place in the oven at 200°C. Stir it every 10 minutes with a metal spatula until it turns golden yellow. Remove from the oven and let cool, then pour into an airtight container.

FollowingI should point out that you don’t want to use liquid gum arabic, because you don’t really know what was used to suspend it. –

Nothing magical.

Thanks! I can’t wait to try it. I have found sources of “food grade” gum arabic and yellow dextran. Do you have a reference source for this process? Have you tried it? –

Angelo

I used references from “The Artist’s Handbook” as well as internet research on historical production methods (and believe it or not, dextrin as a filler for the manufacture of fireworks). a method of doing) as well as my own experience with colloids. I suggested clove oil because it is a common antifouling additive. –

Nothing magical.

I gathered all the ingredients and gave it a shot (see update to my answer)… mixed results, but I’ll try again and be more careful with the yellow dextrin.

I love up-cycling paper by turning it into a DIY envelope, and it’s easy to make several envelopes in one sitting! One thing I don’t like about handmade envelopes? Adhering the top flap with traditional white glue, which can be a hassle and make it difficult for your recipient to open the envelope. With this DIY envelope glue, you can wet seal the top flap of any envelope, just like with commercial envelopes!

DIY envelope glue for handmade envelopes

This is a DIY envelope dampening seal recipe. This means that your handmade envelopes will be just as effective and convenient as commercial envelopes! You can keep your DIY envelopes (by gluing to the envelopes) for yourself, or you can make professional-looking handmade stationery and give it as a gift.

1. Gather your ingredients.

This envelope glue recipe requires four ingredients:

Here are the measurements you need for each:

- 3 tbsp (45 mL) white vinegar

- 1 packet* plain granular gelatin — In the U.S., gelatin is usually sold in packets equal to 0.25 ounces of granular gelatin, or 4 sheets of sheet gelatin.

- 1 teaspoon (5 mL) vanilla extract

- 1 tablespoon (5 mL) white sugar

- 2. Put it all together

First, put the vinegar in a small container and microwave it until it’s warm, about 30 seconds.

Vinegar for DIY envelope glue

Then, add the gelatin to the hot vinegar and stir the mixture until the gelatin dissolves.

- Gelatin for DIY envelope glue

- Next, add in your sugar and stir to combine.

- Making DIY Envelope Glue

- Finally, pour in your vanilla extract and stir. With all four ingredients, you’ll get something that looks like this:

Your mixture should have a consistency similar to maple syrup.

3. Apply glue to the flaps of the envelope.

To use glue, you’ll first need a DIY envelope. You can make your own from any paper, or you can print out a ready-made mail art template. No matter what you choose to do, adhere the bottom flaps of the envelope with regular glue, and leave the top flap free of glue.

Next, take out a brush about 1/2″ wide (~13mm). Brush a single, even layer of envelope glue along the edge of the top envelope flap. If your glue seems thick, microwave it for 5-10 seconds to return it to a thin liquid state.

DIY envelope glue

Do not use a furry brush to apply the glue as the gelatin is hard to clean completely from the bristles!

Allow the glue to dry for 5-10 minutes. It should not feel wet to the touch. At this point, you can moisten it (either with your tongue or a wet cloth). Next, close and seal the envelope — just like you would with a business envelope!

DIY Envelope Glue Applications

Here’s exactly what I would do with this glue: First, set aside about 30 minutes to make several handmade envelopes. Then, apply your glue. Wait a few minutes for the glue to dry, then you can lower the flaps and give the envelopes as gifts or save them for later use.

Once you’re done applying glue to your envelopes, you’ll have leftover glue. Just pour it into a small jar and keep it in your fridge! This will last for several months. Whenever you need to use glue, just put it in the microwave for ~10 seconds to turn it from a solid (cold) state to a liquid. Then, you can reuse it. For envelope templates in several different sizes (and envelope liners to add heft to DIY envelopes), see The Letter Writer’s Complete Resource. It includes five printable handmade envelope templates as well as other helpful tools to help you send beautiful stationery!

This recipe was first published on the TPK blog in 2013. Since then, I have received many questions about it! You’ll find those questions and answers below.

How long with this glue? / The glue will last for several months in the refrigerator. It is a food product, so it will start to rot after a while.

Can you make this glue with only vegan ingredients?

- I do not believe. You can try substituting agar agar or carrageenan for the gelatin. However, I have not tried any of these alternatives and cannot speak to their effectiveness.

- Is the glue still effective over time? Any wet seal glue weakens over time. I guess this glue will last for many years.

- Is it strong glue? This glue appears to be as strong as commercial envelope dampening sealing glue. I think you’ll find that it’s more effective on some papers, however, and less effective on others.

A lot of people don’t send letters anymore. This may be because our laptops, smartphones and tablets have taken over and we now communicate electronically. Or, it could be because envelope glue tastes terrible.

If you were thinking about sending a nice, handmade Valentine’s Day card this year, but the thought of licking all those envelopes made you so disgusted that you changed your mind, you’re in luck.

Over the past week, I’ve been seeing ThinkGeek’s chocolate flavored wrappers all over the internet.

After a quick search, I realized that while chocolate might be the best flavor, they certainly weren’t the only ones doing it. Bacon wrap, anyone?

The only problem (besides the fact that you want to eat the envelope) is that they are very expensive. But, it turns out it’s pretty cheap and easy to make your own.

DIY Flavored Envelope Glue

With just a few basic ingredients, you can make your own envelope glue in any flavor you want. Here is the recipe from The Karate Teacher:

- 4 unflavored gelatin powder

- 6 tablespoons of white vinegar

- 1 tbsp extract of whatever flavor you choose

All you have to do is heat the vinegar to almost boiling, then add the gelatin powder, and mix until it dissolves. The quote is, of course, optional, but what’s the point of making your envelope glue if you don’t make it tasteful?

You can find basic flavors in grocery and cooking stores, and if you’re looking for something a little more exotic, you can find just about any flavor imaginable. Olive Nation has everything from blueberries and pineapple to butter or even bourbon. And, if you love ThinkGeek wrappers, you can recreate them with chocolate extract.

When it comes to using the glue, you’ll want to paint it onto the envelopes with a small brush while it’s hot. If you have some left over, or it gets cold while you’re working with it, you can reheat it later using a double boiler to keep it warm without burning.

Want to master Microsoft Excel and take your work-from-home possibilities to the next level? Jumpstart your career with our premium A to Z Microsoft Excel training bundle from the new Gadget Hacks Shop and get lifetime access to over 40 hours of basic to advanced instruction on functions, formulas, tools, and more.

Make your own envelope glue or stamp paper

This simple technique makes lickable paper for envelopes, stamps and stickers. It’s cheap, fast, and easy, but requires a little planning because the glue needs to dry before use.

Take four packets of unflavored gelatin and dissolve it in about a third of a cup of hot (boiling) white vinegar. You can also add a teaspoon of vanilla extract or other flavorings, although with very young children this may encourage eating the paper. stir well. While the mixture is still hot, use a sterile paintbrush or toothbrush to paint on the back of the paper you want to use. Work fairly quickly, as the mix will begin to gel as it cools. Hang and let dry.

Another recipe involves mixing equal parts vinegar and white glue and applying as above. I’ve never tried it because I tell kids to lick something that has non-nutritive ingredients. (And I’ve probably watched one too many episodes of Seinfeld.) Of course, they could always wet it with a sponge instead.

Once the papers are dry, you lick or otherwise wet the painted side so that it sticks to the other papers. A fun project to create with this recipe would be to have the kids make stamps. They can draw small designs on paper and then cut them out with special stamp-edge scissors (about $2 at a craft store). You can apply the glue before or after making their designs. Put them in envelopes and send them to your friends!

What is a gummed envelope?

We should address this particular question from the beginning because there is often confusion between lost envelopes and self-seal envelopes.

First things first: they are not the same thing.

A gum-sealed envelope, commonly called a “gummed” envelope, has a strip of water-soluble glue or gum on its flap. To seal the envelope, moisten it by licking the gum, moistening the envelope with a moisturizer, or using a mailing machine. After humidification, the flap can be closed and pressed.

Gummed envelopes are the most traditional and widely sold because they are more cost-effective than self-sealing or flip-and-sealing. Simply put: they are the least expensive!

Another advantage of gummed envelopes is that they are an excellent choice for use in bulk mailing machines. Once mail is inserted into the machine, the glue on the flap is automatically wetted and pressed shut, making the envelope and its contents ready for mailing.

What is a self-seal envelope?

Self-seal envelopes are known by many names: peel and seal, strip seal, peel and stick, zip seal, or Super Seal. They are a popular and easy-to-use alternative to traditional envelopes because, unlike lost seals, self-seal envelopes do not need to be moistened. (No licking! No glue sticks! No tasting – hooray!)

Instead, self-seal envelopes come with a sticky band of latex glue on the flap that is covered with a protective strip of paper or plastic. To seal these envelopes, simply peel off the protective strip to reveal the adhesive strip, then fold the flap over and press closed to form a bond.

One downside of self-seal envelopes: They are not recommended for use in bulk mailing machines because they are not equipped to handle the security strip, which creates a problem.

- What is a flip and seal envelope?

- Are flip and seal envelopes the same thing as self-seal envelopes?

Short answer: no.

Long answer: Unlike self-seal envelopes, which have a single adhesive strip on the flap, flip-and-seal envelopes have a latex adhesive strip in two places: one strip on the top flap and one strip on the folded bottom flap, which Goes along. Open edge of envelope.

To flip and seal the envelope, fold the bottom flap to expose the adhesive strip. Next, fold the top flap down so that the two adhesive bands are pressed together. Ta-da! It’s flipped, sealed, and ready to ship.

Flip and seal envelopes are unique in that they offer the convenience of self-sealing – no moisture required – but with the added bonus of extra waste, as there is no protective strip to remove first.

A word of warning about storing the flip and seal envelopes…

It is recommended that flap and seal envelopes be used within 6-12 months of purchase due to the latex sealant on the flaps, which is a different material than the water-soluble gum used with other types of envelopes. Latex can lose its adhesive properties over time, especially when stored in humid conditions, so it usually has a shelf life of 12 months after the date of manufacture.

“But I thought self-sealing envelopes were like flipping and sealing.”

Well… yes and no, depending on who you buy your envelopes from. There can be a bit of confusion here, as some European office supply companies use the term “self-seal” while most North American companies say “flip-and-seal.”

So to clarify again, here at Blue Summit Supplies (an American company) we use the term “self-seal” specifically to refer to envelopes that have a protective strip that can be pulled to seal. The top flap must be peeled off – AKA, “peel and seal.”

In contrast, a “flip and seal” envelope has two adhesive strips on either side of the envelope opening. When you flip the bottom flap over and fold the top one down, the adhesive bands are pressed together to form a seal.

Can adhesive seals on envelopes ruin my printer?

This depends on the type of envelope and printer in question. First, we recommend reading the instructions and/or printing a sample for your specific printer. But in general, standard gummed envelopes perform well in printers, because water-soluble glue usually doesn’t clog printers.

However, neither self-seal nor flip-and-seal envelopes are recommended for use in printers. The protective strip on the self-seal envelope can melt, and the latex glue on the flip and seal will almost certainly block or damage your printer. Instead, we recommend using self-sealing or flip-and-seal envelopes with double windows, which allow you to print your recipient and return addresses directly onto the mail material so that the windows can be seen from Doing so means there’s no printing required – just stamp and send.

Lickable envelope glue

First let me say that I am well aware that you can purchase a lickable glue product to use when making your envelopes. I am also well aware that you can use double sided tape *Oki has used this method himself* as a way to seal an envelope but I wanted to make my own glue dammit!! The reason I say these things is because when I shared about making envelope glue on Facebook, I got people telling me I should do this or that and I didn’t want to do this or that, I just wanted to do that. Wanted what I wanted to do!

I was also told that the glue ingredients in the envelopes are supposed to attract ants and then someone said that it might attract roaches but I’m here to say that I don’t use my envelopes. I didn’t see an ant or a roach. Oh yeah then someone mentioned “it’s not vegan friendly”. By this time I wanted to slap some people on the head. I couldn’t do that by reaching through the computer so I just called Carmen and yelled at her for a while and I felt all better.

Ok now that that is off my chest I will share with you about this great idea!

Ingredients:

- 3 tablespoons of white vinegar

- 1 envelope unflavored gelatin

- 1 teaspoon vanilla extract

- 1 teaspoon of sugar

Use a small container with a lid, I used one of the 4 oz rubbermaid containers in my kitchen cabinet, and put the white vinegar in the container. Place the container in the microwave and heat until the vinegar begins to boil. I believe I did mine for 45 seconds or so but it will depend on your microwave. Remove from microwave, add gelatin and stir until dissolved. Add the vanilla and sugar and stir well to mix.

When done, you should end up with a mixture that looks something like this and it’s ready to use!

I’ve had it stored in my fridge for a few weeks now and I’m still able to take it out and use it without any problems. But make sure you refrigerate it when not in use. It will set but pop it in the microwave for about 30 seconds and it will be thin enough to use again.

I’m not sure how many envelopes one recipe will make but I can say that I think I did over 300 envelopes with one batch I made and I still have quite a bit left over.

You’ll want to use a cheap stiff paintbrush, don’t waste a good paintbrush on it, and then apply to the top flaps of all the envelopes you made with yesterday’s tutorial.

Make sure not to touch anything when the flaps are wet as they will stick. Drying time will depend on how thick you apply the glue and should dry in about 30 minutes or less. After drying you can fold the flap and store it. When you’re ready to use the envelope, simply lick and close like a normal envelope. Oh and you won’t even taste the vinegar so don’t worry about handing out your handmade cards and envelopes and people being grossed out by the taste. It actually tastes better than most wraps I’ve licked.

Envelope glue uses moisture

Consider the glue used on envelopes that require moisture to seal the envelope. This type of glue was usually made from gum arabic, which is the product of the tough sap of two different species of acacia trees, which can be found in West Africa. It is edible to humans and useful for sealing envelopes, as well as being an important ingredient in certain candies such as M&Ms, marshmallows, and gumdrops. Non-edible applications include the binding of watercolor paints and an important ingredient in shoe polish. This is a very useful thing in our world.

Many letters that arrive in my mailbox are poorly sealed to begin with. For most of my life, I licked the glue off one or two letters at a time every day, always careful not to cut the paper on my tongue. When I had a large number of letters to mail, I sometimes ran a wad of water over a paper towel-covered saucer and then dipped my index finger into the envelope to spread the moisture. I also bought a small container with a sponge tip for this purpose. Eventually, I turned to a new type of self-sealing.

When I reach to open my incoming mail, I find that many of these flaps are only half-stitched. Sometimes the entire right half of the flap flutters in the breeze. I suspect this is the result of possible carelessness on the part of the sender, and partly the way the glue was originally applied to the envelope by the manufacturer. I have purchased mailing envelope boxes from several different local office supply stores and none are better than the other. Those stores certainly don’t make their own envelopes, but sell them retail from some other wholesale houses. Some require wetting the flap while others are sealed by removing the tape from the adhesive strip.

This does not apply to greeting cards where standard cards (even cheap ones) are of better quality construction. After my experiences six weeks ago, I began to look more closely at the glue strip. Most of them stop about an inch from the edge of the envelope with no seal at each end. To secure my contents, I’ve started adding a small piece of scotch tape to the end of the flap where I’ve attached something of value (a check, special note, etc.).